DAY 1 - April 1st 2015 MAKING A MARK

Very excited about starting the first day at Leicester of our 2 year Lithography Fellowship! - Everyone really friendly and made us feel very welcome . I am working with Nina Oskarsdottir an Icelandic artist who will be the other Fellow and our tutor Serena Smith.

Stone lithography is a printing process whereby a greasy mark is drawn on to a limestone slab, the stone absorbs the grease and then the stone is then etched with acid . It feels like I am doing a chemistry degree as the science is pretty complex but the process basically involves oil and water repelling and lots of gum arabic !

The greasy image is cleaned off the stone and more etching and gum arabic employed. The stone is inked up but kept damp with water. The oily ink is attracted to the grease in the stone and repelled by the areas that are wet and non greasy. The stone is then printed on a special lithography press. The first prints are quite pale and it takes about 8 - 20 prints before the image is completely developed.

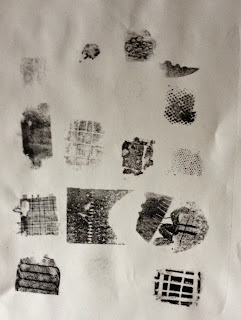

Our first morning was spent experimenting making marks using greasy,dry materials (litho crayons/ tusches/ rubbing blocks) on a fresh stone . I experimented by sticking masking tapes (something I use all the time in my painting) down on the stone, crayoning onto textured wallpaper and impressing on to the block.

A right motley crew of marks was produced but we will see what happens!

DAY 2 - 2/4/15 PREPARING STONES

The stone was left to rest overnight so that the greasy marks could be absorbed and it was protected with a thin layer of gum arabic. (I am learning that if in doubt stick on a layer of gum arabic!) The stones were then etched and then inked as before - 8 prints were taken by using the litho press shown below.

The first prints were made using a 70: 30 mix of Crayon Black ink (which is good for crayon drawings) and Noir A Monter ink which is much softer and makes the ink more workable.The first prints were pretty pale with a lot of the detail missing but became increasingly darker and more detailed with subsequent printing. It was like alchemy seeing the drawing gradually appearing with each subsequent print.

Image on left - first print, image on right eighth print

DAY 3 - 15/4/15 INKING!!

Got a throat infection and feeling rubbish! Learnt today that the secret of all this is in the inking! The viscosity of the inks is particularly important, with different marks responding differently to different thicknesses of ink.

We printed up the stone in a bright red ink using using various extenders (softeners) and thickeners to alter the viscosity. Additives such as plate oil, Graphic Material Base Extender, Intaglio Base Extender, Vaseline and Transparent Base Extender. I learnt the hard way that its better to have ink too stiff and then soften with extenders rather than the other way round!

The softer ink worked better for fine lines and more detailed areas that were not picked up by the Crayon Black ink - however in darker areas of the print it tended to smudge a bit as the ink was too soft. I was really pleased with the marks that the masking tapes made and would like to explore working with these a bit more.

This print was done with red litho ink and a few drops of plate oil

We then tried mixing just with the Noir A Monter ink on its own using a nap roller. The Noir A Monter ink is much softer than the Crayon Black but seemed to work well in both detailed and darker areas of the print. Particularly with the marks made by the masking tape it seemed more subtler and picked up more detail than the crayon black which seemed to give a more solid block of colour.

This print was done using Noir A Monter ink on a Nap roller

Next we looked at how to alter marks that we've made on the stone by additions and removals. Marks were removed by using nitric acid of varying strengths and an oil degreasing agent. Pumice on a scourer was also used to abrade and soften the existing marks producing different gradations of tone. Marks were added by scoring / scraping the stone with a scalpel then rubbing oil into the incised mark. Further additions were made using soap solution and ink but these were not very predictable (and care needed to be taken not to contaminate other areas of the stone with it and being naturally messy I think will take some practice to master!) Its all quite mind boggling and its a good job we have 2 years to assimilate all this !!!

Litho stone printed with Crayon Black and Noir A Monter after various additions and removals. The dense black squiggle in the middle of the print which was not present in earlier prints is soap solution.

DAY 4 - 22/4/15 ADDING COLOUR WITH PHOTOLITHO PLATE

Printed up photo lithography plate using blue etching ink - As mentioned earlier the viscosity of the ink is quite critical ! - initially I added too much extender - (made ink too thin) -so thickener added - Ink was rolled on to plate keeping it wet with a dampening cloth - the paper was registered and then the plate was printed on an etching press. (See below)

Experimented printing stone using different viscosity inks - Crayon black ink (v stiff!) and litho ink - approx 70:30 rolled using normal roller. The stone was kept damp - colour increased markedly with subsequent prints - some areas at bottom ? Too much water ? Not enough pressure? ( I later realised that my stone had moved slightly down the press bed and needed to be budged up a bit!)

Serena also demonstrated washes. Soap dissolved in water and then Indian ink added - (needs to be prepared in advance - 45 minutes or so)

Tusché sticks - (thinner than rubbing blocks - rubbing blocks don't work) were dissolved in turps or water - turps much quicker. Depending on which solvent is used gives different effects - turps tusché much darker and leaves an edge around the mark.

Also experimented painting the turps wash onto the stone and adding water with a separate brush. - This gave watery droplet effects and interesting marks produced.

Can also draw with gum Arabic first and paint turps wash on top - gum Arabic remains clear and visible on stone afterwards.

Charbonnel ink also used with a nib - more watery

DAY 5 - 23/4/15 - GRAINING STONES

Graining Stones - I now know where the phrase 'back to the grindstone' originated from!' This was hard work but once you got into the groove strangely theraputic ! It basically involves rubbing a block of limestone the size of 2 bricks in a figure of 8 pattern over the surface of the lithography stone using different grains of grit between the 2 stones which acts an as an abrasive- for about 1 1/2 hours! I think I am going to look like a female bodybuilder by the end of our 2 years but at least all this will get rid of any bingo wings!

To clean the stone to prepare for a new image any ink from the last print is removed with turps and a damp rag - Oil cleaner is brushed on and the surface agitated and left no longer than 30 mins -The oil cleaner is then removed - it is a powerful degreasing agent and pretty toxic so care should be taken when using it.

Citric acid is poured on to the stone and then scrubbed with a scourer. It is then washed off - a little ink is rubbed on a turpsy rag to see if image is still visible. The stone is then ground using coarse grit for 30 mins and 2 small stones on top of each other for extra pressure. Then just one grinding stone is employed with medium grit for 30 mins and finally fine grit for 30 mins.

Tusché sticks - (thinner than rubbing blocks - rubbing blocks don't work) were dissolved in turps or water - turps much quicker. Depending on which solvent is used gives different effects - turps tusché much darker and leaves an edge around the mark.

Also experimented painting the turps wash onto the stone and adding water with a separate brush. - This gave watery droplet effects and interesting marks produced.

Can also draw with gum Arabic first and paint turps wash on top - gum Arabic remains clear and visible on stone afterwards.

Charbonnel ink also used with a nib - more watery

DAY 5 - 23/4/15 - GRAINING STONES

Graining Stones - I now know where the phrase 'back to the grindstone' originated from!' This was hard work but once you got into the groove strangely theraputic ! It basically involves rubbing a block of limestone the size of 2 bricks in a figure of 8 pattern over the surface of the lithography stone using different grains of grit between the 2 stones which acts an as an abrasive- for about 1 1/2 hours! I think I am going to look like a female bodybuilder by the end of our 2 years but at least all this will get rid of any bingo wings!

To clean the stone to prepare for a new image any ink from the last print is removed with turps and a damp rag - Oil cleaner is brushed on and the surface agitated and left no longer than 30 mins -The oil cleaner is then removed - it is a powerful degreasing agent and pretty toxic so care should be taken when using it.

Citric acid is poured on to the stone and then scrubbed with a scourer. It is then washed off - a little ink is rubbed on a turpsy rag to see if image is still visible. The stone is then ground using coarse grit for 30 mins and 2 small stones on top of each other for extra pressure. Then just one grinding stone is employed with medium grit for 30 mins and finally fine grit for 30 mins.

After all that exertion we had a gentle hour or so experimenting with liquid tusches using both water and turps as the carrier medium. Here s the stone I worked on:

I used a mixture of liquid and dry tusches. Soap solution was used for the trees together with litho crayon, Turpsy tusche wash was used with water splashed at the bottom of the stone and above this I painted a watery tusche wash. I used masking tape as seen, rubbing blocks dabbed on to the stone directly and also indirectly by pressing on to walllpaper and liquid charbonnel ink with a pen for the graffitti. I had forgotten to reverse the image so it will print backwards but no worries as this is only a test!

I used a mixture of liquid and dry tusches. Soap solution was used for the trees together with litho crayon, Turpsy tusche wash was used with water splashed at the bottom of the stone and above this I painted a watery tusche wash. I used masking tape as seen, rubbing blocks dabbed on to the stone directly and also indirectly by pressing on to walllpaper and liquid charbonnel ink with a pen for the graffitti. I had forgotten to reverse the image so it will print backwards but no worries as this is only a test!

The etching process of the stone seems very complicated - different marks require different acid strengths. Because water touches are more unstable they have to be treated with stronger acids. The acid is painted on to selected areas using quick brush strokes - In areas where I had used rubbing block we used a broad brush liberally soaked in atzol (an acid mix of gum arabic) so as not to cause striations from brush marks The stone was left to rest until next week.

DAY 6 - 29/4/15

The stone we prepared last week had its edges filed so that there were no sharp edges that would damage the roller. the edges were treated with strong nitric acid to remove any extraneous marks.

A second etch was placed on the drawing strategically - weaker watery marks are treated with weaker acids some of the drawing was n't etched at all - merely protected with a thin layer of gum arabic. This bit seems really complicated - knowing what strength of acid will get the best out of the marks but I guess its just a case of experimenting as much as possible to see what works (or not!). The stone was then dried and then left to rest.

While that was resting - it was back to the bunker to grind clean our first test stone !

DAY 7 - 30/4/15 TRANSFER PRINTS

Serena showed us a great technique for transferring marks onto the stone using gum Arabic transfer paper. It works a bit like the stick on transfers you used to get in bubble gum packets as a kid which when dampened cause the image to be transferred. You can take rubbings, cut it and transfer it like collage, scratch into it, add masking tapes , draw on it - the possiblities seem endless! I spent a happy hour cutting up about 15 different transfers to stick on to the stone.

The stone was then wet thoroughly and the press adjusted so that the pressure was quite light. The transfers were placed quickly down onto wet stone and covered with acetate and news print then run through the press 2 times. The transfer paper was gently re wet with a moist sponge repress and this procedure repeated 4-5 times until the drawing started to show through. When that occurred the transfer was gently removed and the stone dried with

French talk and gum Arabic.

Litho stone showing marks made from transfer papers

Ten prints were then taken from the tree landscape stone for proofing using Noir A Monter ink and a nap roller. As before they became gradually darker with each subsequent print.

first print

last print

6/5/15

Bit scary as this is the first day that we have to go it alone as Serena is n't here to guide us today!! Fortunately she has left detailed instructions of what to do and there is always the trusty Nina to ask (who seems to have assimilated the process much better than I have !)

Experimented with tree landscape -(image that I started last week) by adding and deleting marks as we did before. Scratched in lines using scalpel and then rubbing ink in (like we did when registering stone) and added further areas with soap solution in ink and water. I then used acid to lighten areas to try and get different tonal variations. Then washed off and gummed and dried. Stone left to dry overnight.

Before additions and subtractions

After additions and subtractions

I then etched the transfer stone - Serena suggested using weaker acid than usual so I diluted the standard Atzol solution (which is 70% gum arabic and 30% nitric acid) with equal parts of gum arabic.The stone was left a couple of hours to dry then washed out and rolled up with a thin layer of Noir A Monter ink and a nap roller.

A second etch was then done using the diluted atzol again.The edges were filed and treated with strong acid to clean them up and then protected with the gum arabic.

Thurs 7/5/15 -

The press was set for the transfer stone. And the previous ink washed out. An ink mix of Crayon Black and Noir A Monter (50:50) was rolled onto transfer with small roller. 8 prints on newsprint 2 on Lambeth paper were taken

Print using 50:50 CB and NAM ink

Then switched to NM on nap roller to get softer marks -

Then tried experimenting with colour and mixed up a concrete coloured opaque ink (litho inks - white, violet, green, blue black brown ) and rolled on with small roller - worked quite well 2 prints on newsprint - 1 on Lambeth.

Then tried using transparent inks (the etching extender is white transparent ) - very runny - ended up adding thickener as well - rolled on with thin roller - couple of prints taken- ink a bit purpley! But the ink worked quiet well and was n't as translucent as I thought it would be. I then rolled some of the same ink on to a photo litho plate and created a stencil to monoprint blocks of colour on top - worked well.

Stone with stencil on after had been rolled with translucent ink on a photo litho plate.

Print with monoprint on top to give colour

The stone was then washed out and gummed and a thin layer o noir a monter rolled on.The stone was French Chalked and gummed again.

Next week concentrate on landscape stone - wash up and noir a monter with nap roller

Additions / removals to transfer stone .?

The stone we prepared last week had its edges filed so that there were no sharp edges that would damage the roller. the edges were treated with strong nitric acid to remove any extraneous marks.

A second etch was placed on the drawing strategically - weaker watery marks are treated with weaker acids some of the drawing was n't etched at all - merely protected with a thin layer of gum arabic. This bit seems really complicated - knowing what strength of acid will get the best out of the marks but I guess its just a case of experimenting as much as possible to see what works (or not!). The stone was then dried and then left to rest.

While that was resting - it was back to the bunker to grind clean our first test stone !

DAY 7 - 30/4/15 TRANSFER PRINTS

Serena showed us a great technique for transferring marks onto the stone using gum Arabic transfer paper. It works a bit like the stick on transfers you used to get in bubble gum packets as a kid which when dampened cause the image to be transferred. You can take rubbings, cut it and transfer it like collage, scratch into it, add masking tapes , draw on it - the possiblities seem endless! I spent a happy hour cutting up about 15 different transfers to stick on to the stone.

The stone was then wet thoroughly and the press adjusted so that the pressure was quite light. The transfers were placed quickly down onto wet stone and covered with acetate and news print then run through the press 2 times. The transfer paper was gently re wet with a moist sponge repress and this procedure repeated 4-5 times until the drawing started to show through. When that occurred the transfer was gently removed and the stone dried with

French talk and gum Arabic.

Litho stone showing marks made from transfer papers

Ten prints were then taken from the tree landscape stone for proofing using Noir A Monter ink and a nap roller. As before they became gradually darker with each subsequent print.

first print

last print

6/5/15

Bit scary as this is the first day that we have to go it alone as Serena is n't here to guide us today!! Fortunately she has left detailed instructions of what to do and there is always the trusty Nina to ask (who seems to have assimilated the process much better than I have !)

Experimented with tree landscape -(image that I started last week) by adding and deleting marks as we did before. Scratched in lines using scalpel and then rubbing ink in (like we did when registering stone) and added further areas with soap solution in ink and water. I then used acid to lighten areas to try and get different tonal variations. Then washed off and gummed and dried. Stone left to dry overnight.

After additions and subtractions

I then etched the transfer stone - Serena suggested using weaker acid than usual so I diluted the standard Atzol solution (which is 70% gum arabic and 30% nitric acid) with equal parts of gum arabic.The stone was left a couple of hours to dry then washed out and rolled up with a thin layer of Noir A Monter ink and a nap roller.

A second etch was then done using the diluted atzol again.The edges were filed and treated with strong acid to clean them up and then protected with the gum arabic.

Thurs 7/5/15 -

The press was set for the transfer stone. And the previous ink washed out. An ink mix of Crayon Black and Noir A Monter (50:50) was rolled onto transfer with small roller. 8 prints on newsprint 2 on Lambeth paper were taken

Print using 50:50 CB and NAM ink

Then switched to NM on nap roller to get softer marks -

Then tried experimenting with colour and mixed up a concrete coloured opaque ink (litho inks - white, violet, green, blue black brown ) and rolled on with small roller - worked quite well 2 prints on newsprint - 1 on Lambeth.

Then tried using transparent inks (the etching extender is white transparent ) - very runny - ended up adding thickener as well - rolled on with thin roller - couple of prints taken- ink a bit purpley! But the ink worked quiet well and was n't as translucent as I thought it would be. I then rolled some of the same ink on to a photo litho plate and created a stencil to monoprint blocks of colour on top - worked well.

Stone with stencil on after had been rolled with translucent ink on a photo litho plate.

Print with monoprint on top to give colour

The stone was then washed out and gummed and a thin layer o noir a monter rolled on.The stone was French Chalked and gummed again.

Next week concentrate on landscape stone - wash up and noir a monter with nap roller

Additions / removals to transfer stone .?

.JPG)

.JPG)

.JPG)

.JPG)

.JPG)